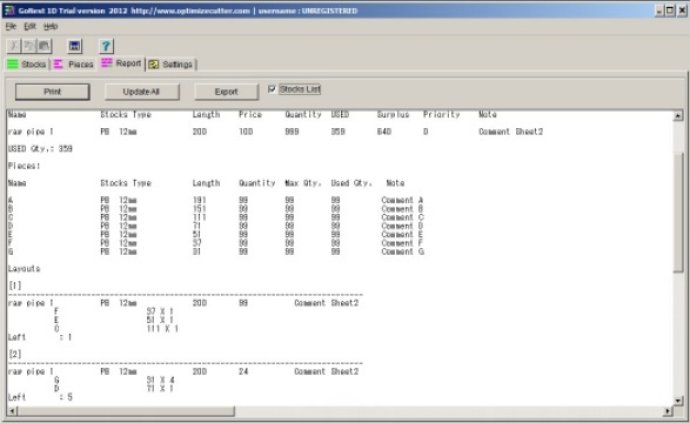

Cutting Optimizer is a 1D nesting software that optimizes stock cutting utilization, reduces material waste and cost. It effectively maximizes efficiency in cutting operations.

The optimizer objective, as well as other optimizer settings such as saw blade width, are in place to ensure that you get the best cutting results with minimal material loss. The term "Stock Material Length" is associated with different forms of stock, such as bars, water pipes, aluminum tubing, aluminum windows, aluminum fences, steel, PVC, glass water pipes, water tubes, wood, boards, beams, wires, iron, strips, timber, rods, columns, glass, aluminum, concrete, building material, wood working, steel building, aluminum tubing, and aluminum fences.

This software is designed to work with any measure of limited capacity, be it the real total width of stock rolls, which need to be cut into narrower rolls (1D nesting cases), or the container to load weight (1D packing case). With GoNest 1D, the optimizer typically reduces stock material from 5-20 times which equates to about 10% to 1% of manual cut planning. Therefore, it's a valuable program that saves time and the level of experience required for cut planning and managing significantly.

Version 2012.10.22: N/A