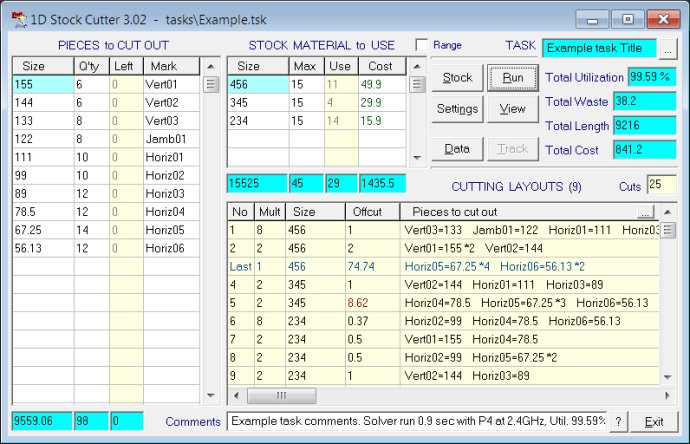

This software optimizes the cutting of linear materials such as metal profiles, bars, and lineal wood, to reduce material waste and cost. It is easy to use and can decrease waste from 10% to 1%.

With its ability to solve the One-dimensional Bin Packing Problem (1DBPP), 1D Stock Cutter can distribute any number of pieces with mostly different lengths among a number of larger uniform or different stock lengths in order to minimize material waste and associated costs. Users can adjust the optimizer goal and technology settings, such as minimal reusable length, trim losses, piece gripping end, and saw blade thickness.

This software tool typically reduces stock material waste by a factor of 5-15 (from about 10% to about 1%) compared to manual cut planning. Plus, it supports network data sharing and has full data import/export capabilities via common text files in adjustable formats.

Need to print solution reports, layout charts, or piece labels? 1D Stock Cutter has got you covered, with full capabilities for printing in both decimal and fraction formats. So why wait? Try 1D Stock Cutter today and optimize your cutting process like never before!

Version 3.11: Layout sequencing for for less stacking space