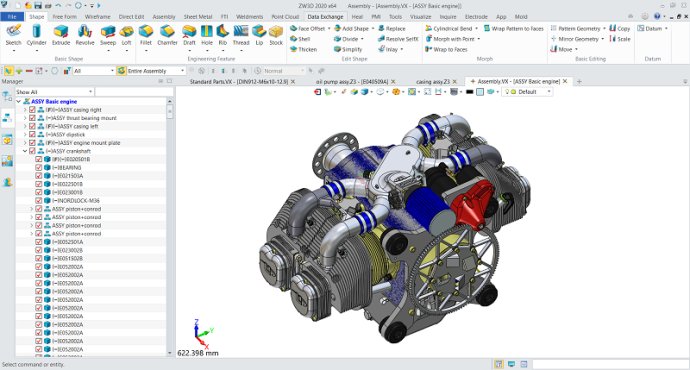

ZW3D is a cost-effective CAD/CAM software that facilitates end-to-end product design in a harmonious and integrated working environment. Additionally, it allows for easy importing/exporting of CAD files with industry-leading software like CATIA, Inventor, and SolidWorks for collaborative design.

This all-in-one 3D CAD/CAM solution can replace the need for standalone CAD and CAM software. The integrated system simplifies 3D data management and facilitates its transition. This feature provides more effective management for users, saving time and subsequently increasing their productivity.

ZW3D is equipped with unique Solid-Surface Hybrid Modeling technology. This feature breaks down the barriers between solid and surface features, granting designers more creativity and opportunities in the design process. The technology enables designers to unleash their 3D design ideas to the maximum potential.

The software also features a cutting-edge Non-solid Mold Parting Technology, enabling designers to create molds that are based on non-perfect solid features. This technology allows users to design molds and create core and cavity faster than ever before. Skipping the model healing shortens the entire mold production process from cost evaluation to manufacturing.

In addition, patented QuickMill Technology allows roughing tool paths with uniform cutting loads, increasing the machining efficiency of CNC machines. QuickMill Technology manages feed rates using the Advanced Feed Rate Control function, lengthening tool life and reducing tool costs.

ZW3D offers an excellent user experience. The user-friendly MS Office-style interface, tutorial videos, knowledge base, and professional support team facilitates a fast software implementation and short learning curve. The Show-n-Tell feature is especially advantageous, allowing the software to operate with its superior functionality.

Overall, this innovative software offers many advantages and provides an all-in-one platform that simplifies the complicated process of product generation.

Version 2020:

CAD

·Flange with Profile

·Enhanced Assembly

·Auto Drafting

Mold

·New Cooling Loop

·Tools for Standard Parts

·Updated Electrode Module

CAM

·Full Machine Simulation

·3D Equidistant Step Size

·Faster Batch Calculation

Version 2019:

CAD

· Better Performance on File Compression

· Upgraded File Translator

· New Sketch Block

Sheet Metal

· Improved Full Flange and Partial Flange

· Enhanced Swept Flange

· New Hem Flange

CAM

· New Flat Finishing Operation

· New Mill-Turn Simulation

· New Form Cutter Engraving

Version 2018SP:

CAD

· Better Performance on File Compression

· Upgraded File Translator

· New Sketch Block

Sheet Metal

· Improved Full Flange and Partial Flange

· Enhanced Swept Flange

· New Hem Flange

CAM

· New Flat Finishing Operation

· New Mill-Turn Simulation

· New Form Cutter Engraving

Version 2018:

CAD

· Better Performance on File Compression

· Upgraded File Translator

· New Sketch Block

Sheet Metal

· Improved Full Flange and Partial Flange

· Enhanced Swept Flange

· New Hem Flange

CAM

· New Flat Finishing Operation

· New Mill-Turn Simulation

· New Form Cutter Engraving

Version 2017SP:

CAD

· Better Performance on File Compression

· Upgraded File Translator

· New Sketch Block

Sheet Metal

· Improved Full Flange and Partial Flange

· Enhanced Swept Flange

· New Hem Flange

CAM

· New Flat Finishing Operation

· New Mill-Turn Simulation

· New Form Cutter Engraving

Version 2017:

CAD

· Upgraded Translator

· New Product Manufacturing Information (PMI)

· New 3D Sketch

· New Assembly Alignment

· Much Improved 2D Sheet

· Expansive Sheet Metal

· Advanced FTI

CAM

· New Path Pattern Guide

· Simplified Cut Boundary Setting

· New Region Order Control

· Better 3X Finishing